Dayton

Die Cushions

Dayton

Die Cushions Dayton

Die Cushions Dayton

Die Cushions |

||

| 6330

Industrial Dr, Eden Prairie Mn 55346, USA |

|

|

|

Pin Pad, also called wear plate, is the top plate of

the die cushion that provides the support for die pins. The standard pin

pad is made out of through hardened and ground steel. If pin pad needs

to be particularly thick due to its size and/or cushion tonnage, it can

be made out of mild steel with though hardened wear plate or strips mounted

on top of it. The plate is hardened to prevent wear from die pins that

ride on top of it. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pin pads can

be designed to be bigger if the required pin pattern coverage area is

larger than standard. They can be mounted independently to each die cushion

or be common for two or more die cushions. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

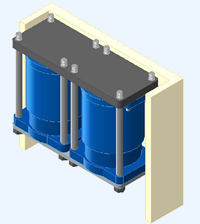

Common Pin

Pad |

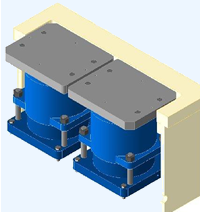

Independent

Pin Pad For Each Cushion |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

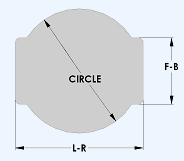

| Pin pads can

be designed to be bigger if the required pin pattern coverage area is

larger than standard. They can be mounted independently to each die cushion

or be common for two or more die cushions. Pin pad's main function is to support die pins load, so deflection analysis is always perform to establish necessary plate thickness so that it deflection is minimized. The other important aspect of pin pad design and die cushion usage is appropriate die cushion loading. Die pins must always symmetrically load pin pad. Even with generous overlap and internal bronze guiding, die cushion cannot be used under off-center loading condition. Please refer to Off-Center Loading page for more information. Also related to off-center loading is the maximum pin pad size that can be mounted on each die cushion. Is is defined by the amount of the overhang pin pad can have per side. It is the distance from die cushion edge to the pin pad edge. Based on that the maximum pin pad size is determined. For low pressure cushions, the maximum overhang per side is equal to 25% of die cushion diameter. This amount increases to 33% for high pressure cushions thanks to their internal bronze guiding. If pin pad is too big compared to die cushion size, even with symmetric die pin load, it can cause die cushion damage similar to one cause by off-center loading. Table below gives the maximum pin pad size for all die cushion series. It also includes common pin pad size for the bank of 2 and 3 die cushions. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Additional Information | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Die Cushion Tonnage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Press Tonnage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tonnage for drawing shells | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||