|

|

|

All Dayton Pneumatic Die Cushions are thoroughly

lubricated at the factory prior to shipment. It is advisable, however,

to lubricate each fitting until grease emerges from between the piston

and cylinder walls before cushion is put into operation. The same

procedure should be followed after every 8 hours of operation. If

the cushion is permitted to stand idle for a period of two or three

weeks, the grease may dry out and as a result the packing will become

hard and will possibly cause an air lack until it has softened up

sufficiently. It may be necessary in some cases to inject grease into

the lubrication system to soften up these packings so that they will

retain their resiliency. A standard automotive pressure grease gun

can be used an all lubricating fittings on Dayton pneumatic die cushions.

Pressure fittings are located either at the front or on the side of

each individual model C, D, MC and MC the cushion piston. They are

installed at the factory prior to shipment.

On some installations, particularly in the larger sizes, the press

bed is so constructed that the grease fittings are not accessible.

The lubrication of the cushion unit on installations of this type

can be easily provided for by centralized lubrication. The centralized

lubrication system consists of a header block and 3/16" copper

tubing that connects this header block directly to the die cushion

unit. The header block is provided with as many grease fittings as

there are in the complete cushion installation. These header blocks

can be placed in any convenient location on the press and will permit

easy and positive lubrication of all the necessary points on the cushion

units. In addition to the copper tubing, all other fittings required

for making the complete installation are furnished. This principle

can be applied equally to both low and high pressure installations.

After centralized lubrication system has been installed, fill the

lines with grease until it emerges from between the piston and cylinder

walls. Check again after 8 hours operation to see how many shots are

necessary to again cause grease to emerge. Thereafter lubricate this

amount every 8 hours of operation. |

|

|

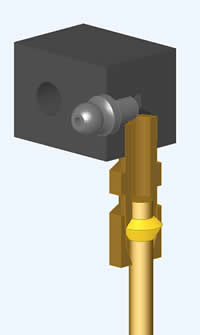

Header Block

Assembly For Both Low And High Pressure Cushions |

|

Header Block |

|

1 Stage |

15467 |

2 Stage |

6985 |

3 Stage |

703 |

4 Stage |

637 |

Grease Fitting |

625 |

Male Connector |

2853 |

Compression Sleeve |

867 |

Nut |

6407 |

3/16" Copper Tubing |

629 |

|

Low Pressure Cushion Grease

Fitting Assembly For Centralized Greasing |

| |

Compression Union |

869 |

Compression Sleeve |

867 |

Nut |

6407 |

3/16" Copper Tubing |

629 |

|

High Pressure

Cushion Grease Fitting Assembly For Centralized Greasing |

| |

Compression Union |

869 |

Compression Sleeve |

867 |

Nut |

6407 |

3/16" Copper Tubing |

629 |

|

|

|

|

Dayton

Die Cushions

Dayton

Die Cushions Dayton

Die Cushions

Dayton

Die Cushions